- Hole dug

- Septic tank and drain field installed

- Well drilled

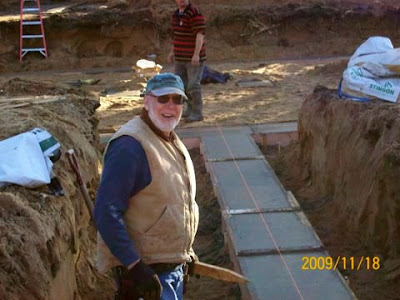

- Footings framed and poured

- Crawl space framed

- Basement beam installed

- Floor joist installed

- Floor capped off

- Tar applied to exterior of crawl space

With a solid cost estimate in hand, the next step in the process was getting financing. Since we are building in Northern Minnesota it made sense to try to get financing from a local bank. Local banks are very familiar with local building codes and local contractors. You might not get the best possible construction loan interest rate, but be less of a headache than having to deal with an out of town lender. After talking with a couple of different banks we found one that was offering acceptable residential construction loan rates. Also, they didn't require a cash down payment since we would be using the land as collateral. The approval process was painless, and there wasn't an unreasonable amount of paperwork required.

At this point it was the middle of October. In Northern Minnesota it gets cold in November and we usually get snow at the beginning of the month. We needed to get the hole dug and concrete poured ASAP. Before we could dig we still had a bunch of paperwork that needed to completed.

The survey was on the critical path and unfortunately the survey company told us that it was going to take 2 weeks before they could get started on it. We waited patiently and the survey was eventually completed at the beginning of November. We now had a 7.84 acre of parcel of land to work with. Luckily the weather was mild during this time. It took an additional week to get the rest of the paper work completed, and on Friday Nov 13th were finally ready to close. Everything went smoothly at closing except that there was a small tax lien against the property. It turned out to be a mistake, and we were able to close as scheduled. Arrangements were made to start digging the hole on Monday.

With a house plan in place the next step was to figure out how much it was actually going to cost to build. Sorry, but I won't be including any actual cost figures in my posts. My father had recently built a house with a similar floorplan, so he had a pretty good idea of what the labor\materials would be. To nail down the numbers, we collected bids from the various subcontractors and the lumber yard.

Here's a breakdown of the major items:

My father and his crew will be doing the framing, drywall, finish carpentry, siding and roofing. My brother and I plan to put sweat equity into the home by doing the following without using a sub-contractor.

Once we knew the cost of building the home we needed to figure out how much we could expect to sell it for. We don't know if we'll be using a realtor to sell the house, so we opted not to bring one in to help us with an estimate. I started by looking at the MLS for comparable homes in the area. Unfortunately, there weren't a lot of comparables. The good news is that there isn't much new construction right now, so our property should compare favorably to many of the older homes on the market. Besides the MLS, Better Homes and Gardens http://www.bhgrealestate.com/ and http://www.zillow.com/ have some nice tools for estimating the value of homes in the neighborhood. The sites aren't perfect, but I found them to be useful in providing a variety of different information. After a lot of research we settled on a target sales price. After taking into account commissions, interest payments, closing costs and a potentially long selling cycle (9-12 months) we felt confident that the profit margin was large enough to pursue the project.